ARCH 202 - STUDIO GUO - TOUCH/SCREEN

PROJECT BRIEF

”The Touch/Screen should be designed as an expression of architectural ideas. The role of the screen should be explored architecturally including privacy, framing of views, mitigating light, mitigating sound, and addressing movement. Our screen requires not just designing what experiences will be facilitated by the screen but also how we actually construct the screen. Tectonics or the art of joining is the center piece of the design of the screen. How can the connections among parts provide for the opportunities for the screen to perform in various conditions and produce a diversity of effects?”

”The Touch/Screen should be designed as an expression of architectural ideas. The role of the screen should be explored architecturally including privacy, framing of views, mitigating light, mitigating sound, and addressing movement. Our screen requires not just designing what experiences will be facilitated by the screen but also how we actually construct the screen. Tectonics or the art of joining is the center piece of the design of the screen. How can the connections among parts provide for the opportunities for the screen to perform in various conditions and produce a diversity of effects?”

Touch - Designing with all our senses Screen - A permeable membrane

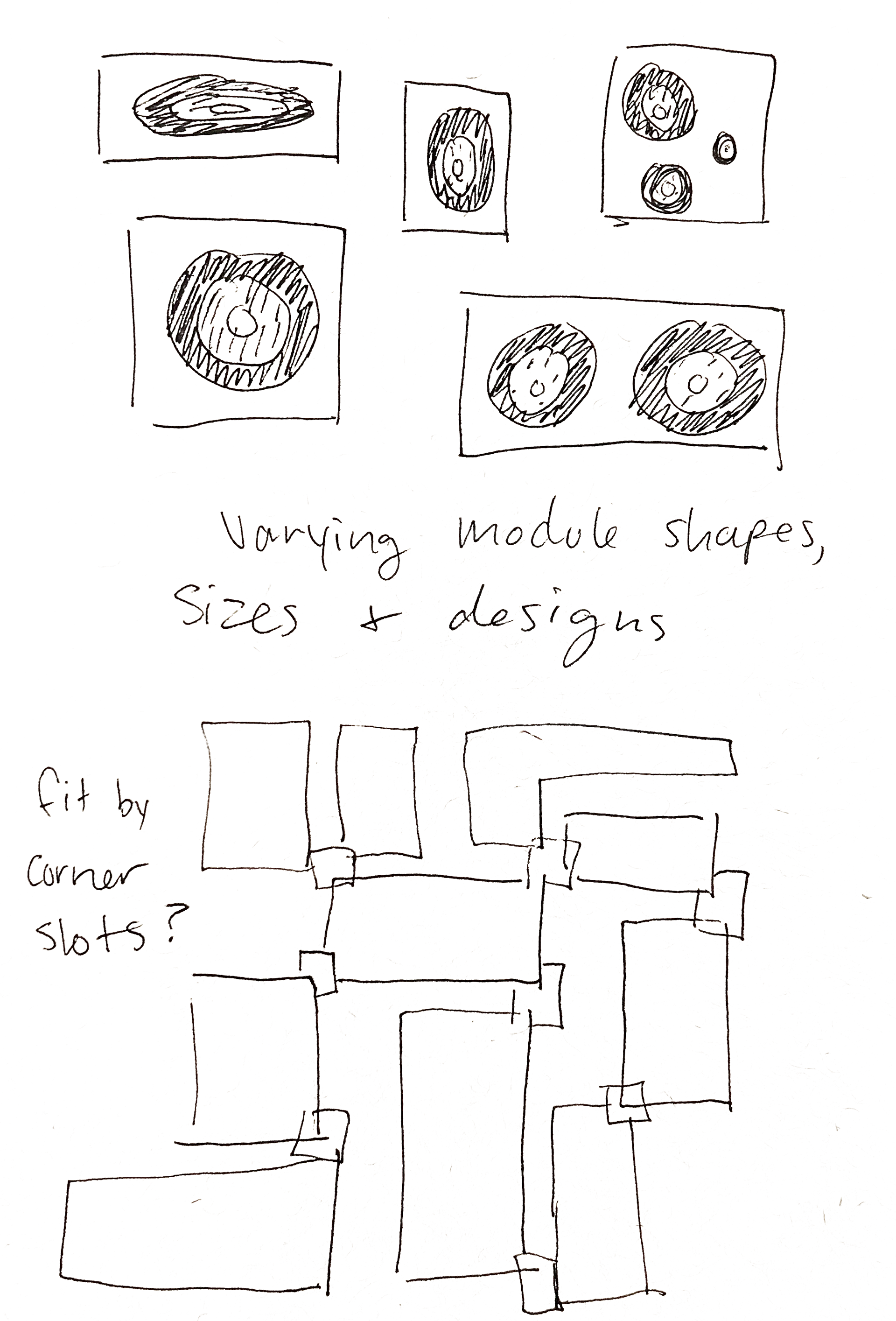

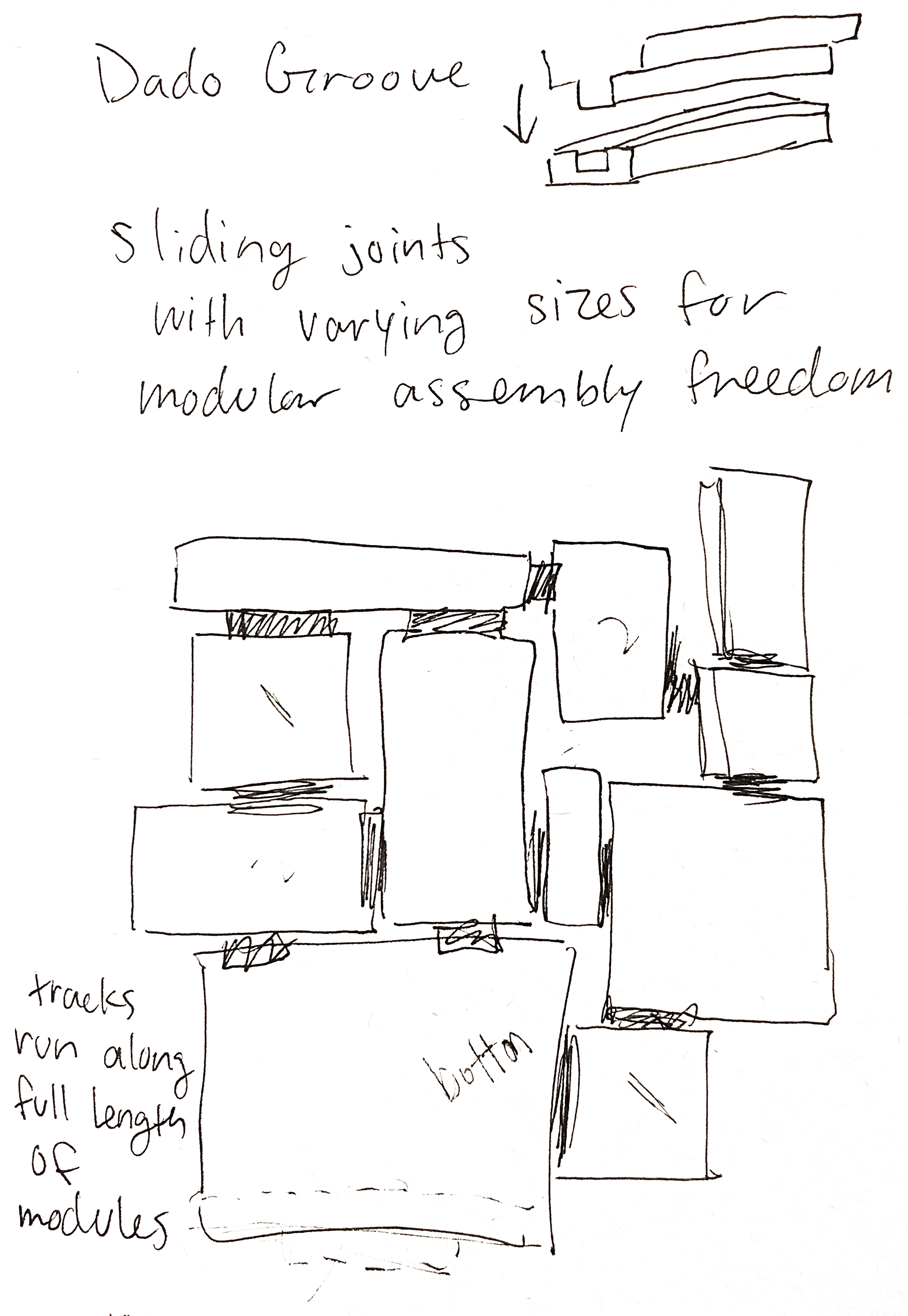

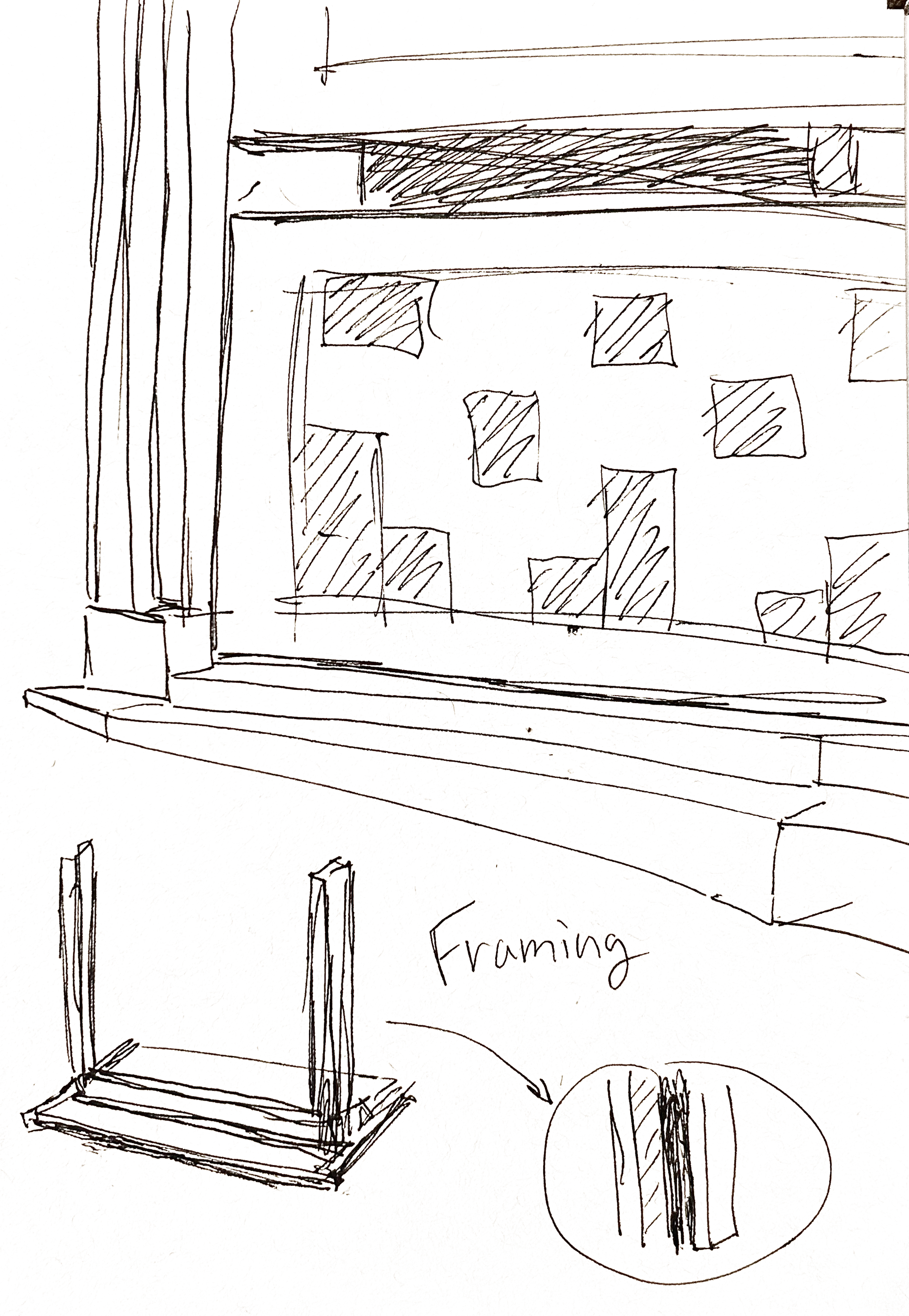

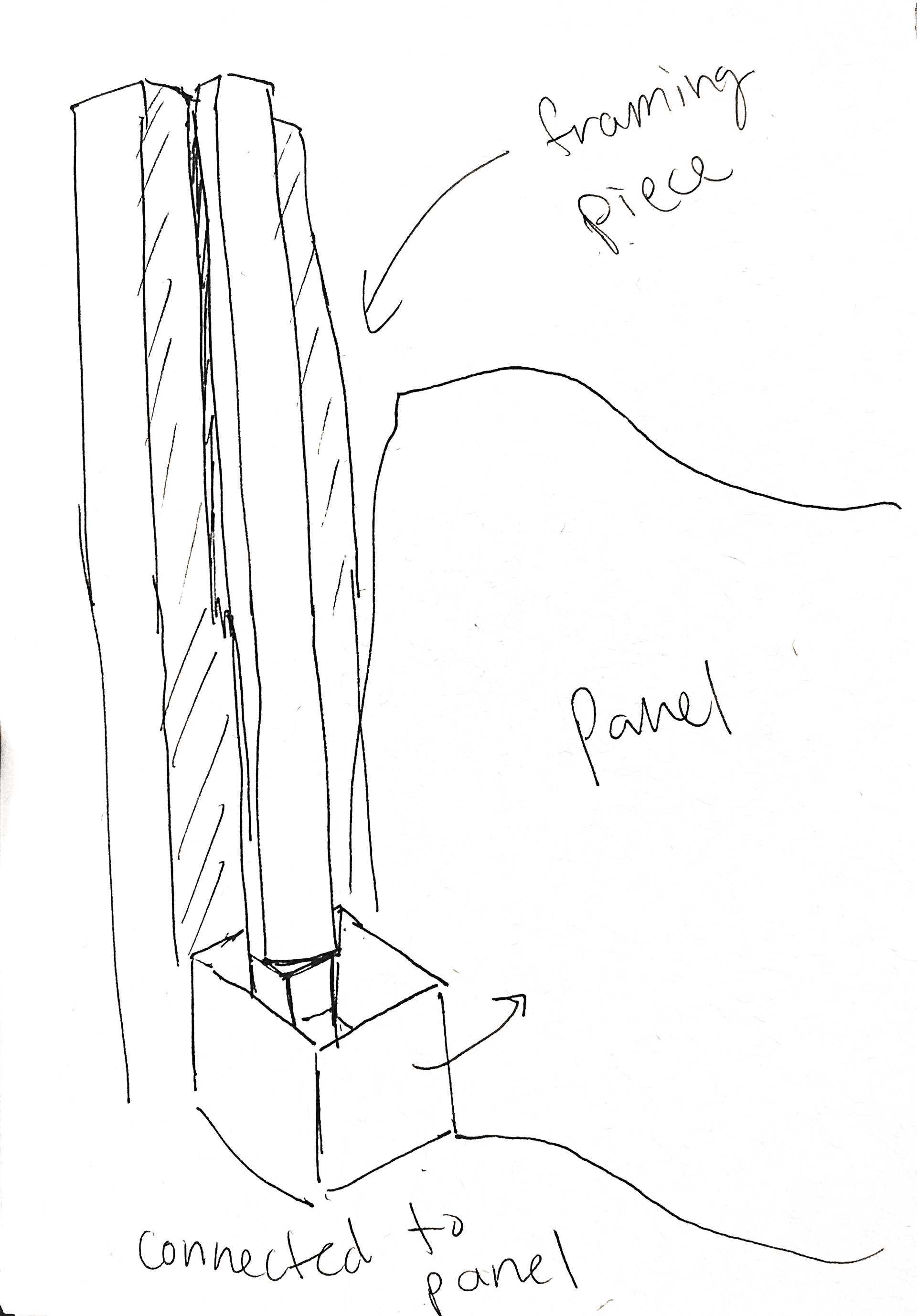

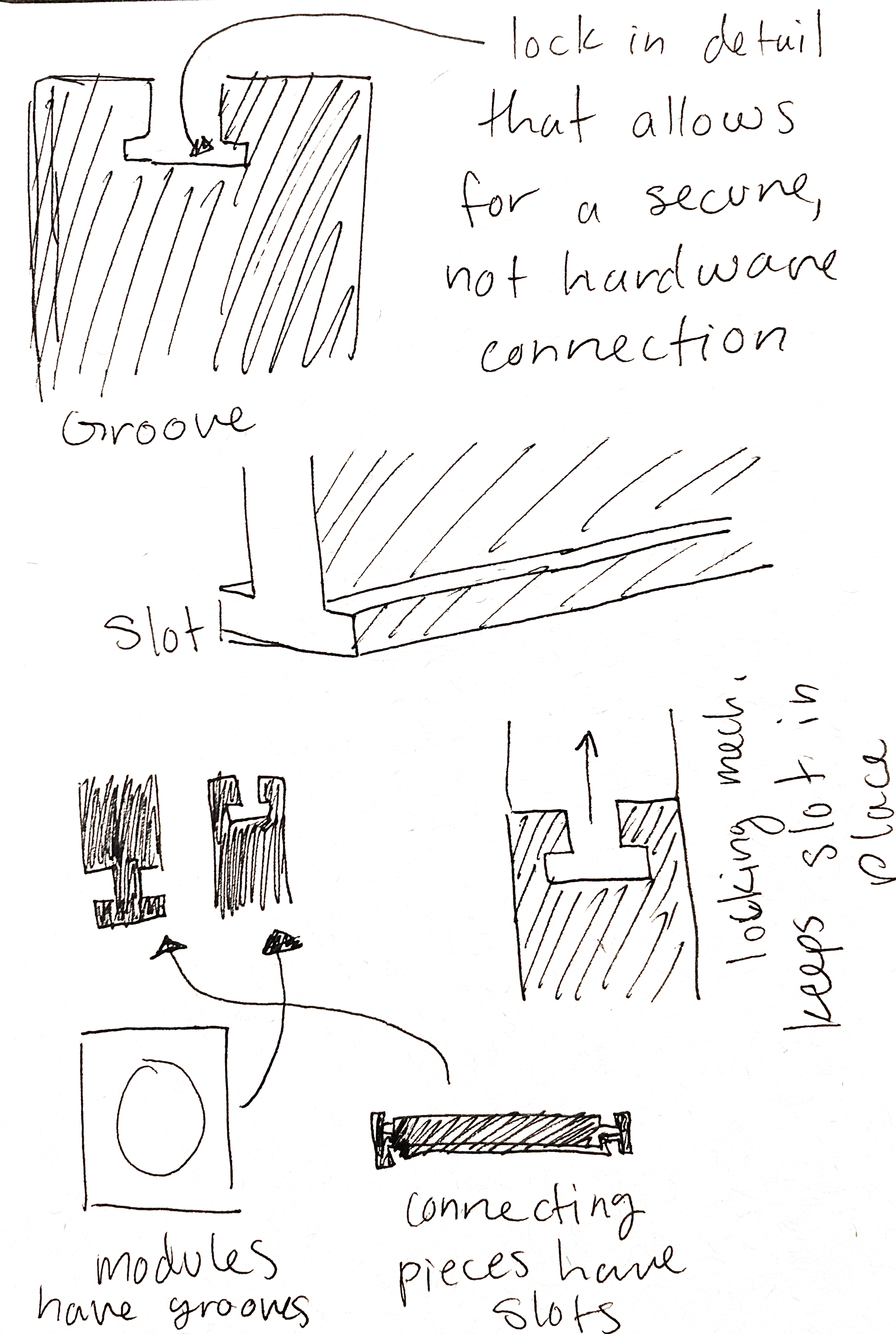

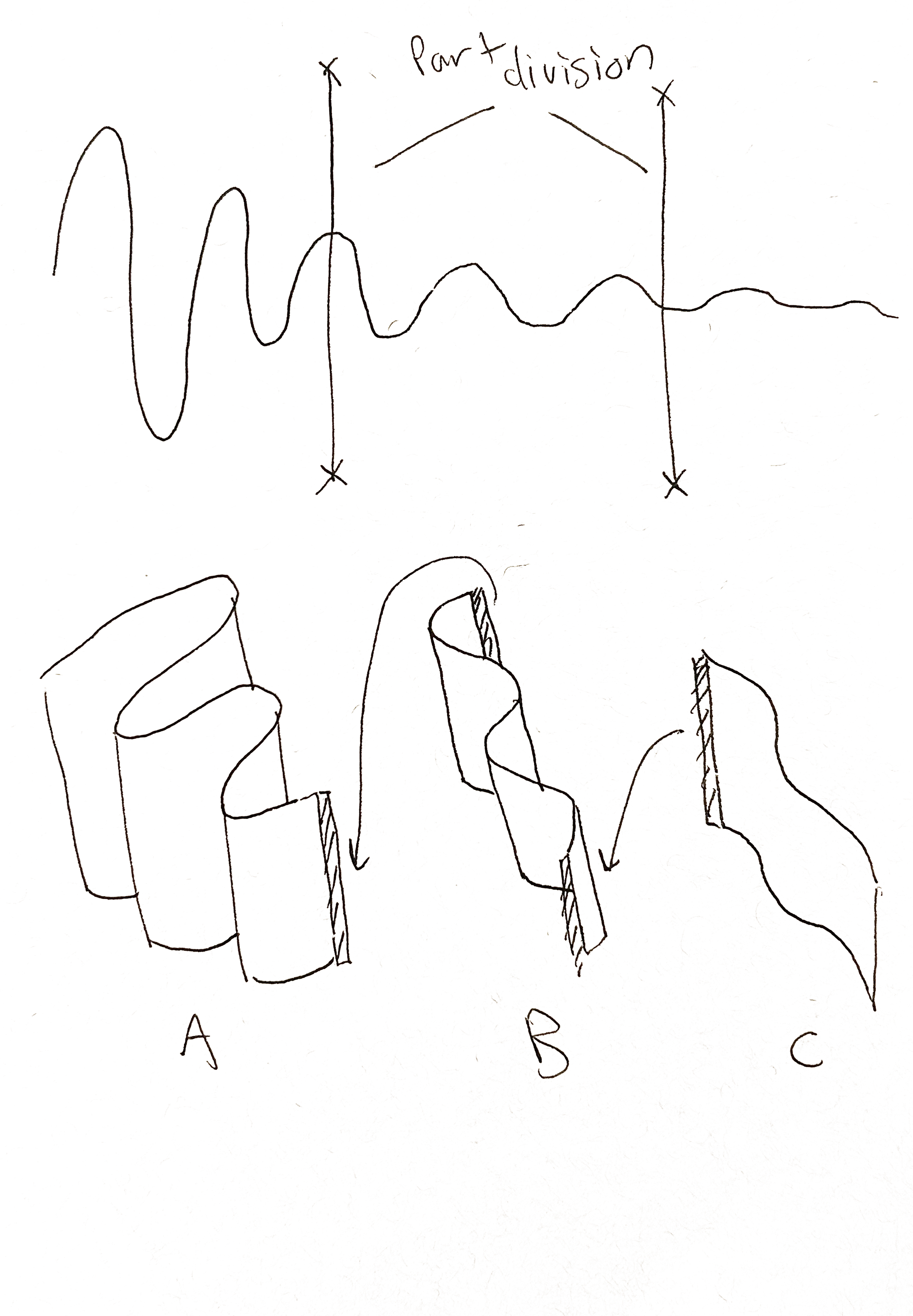

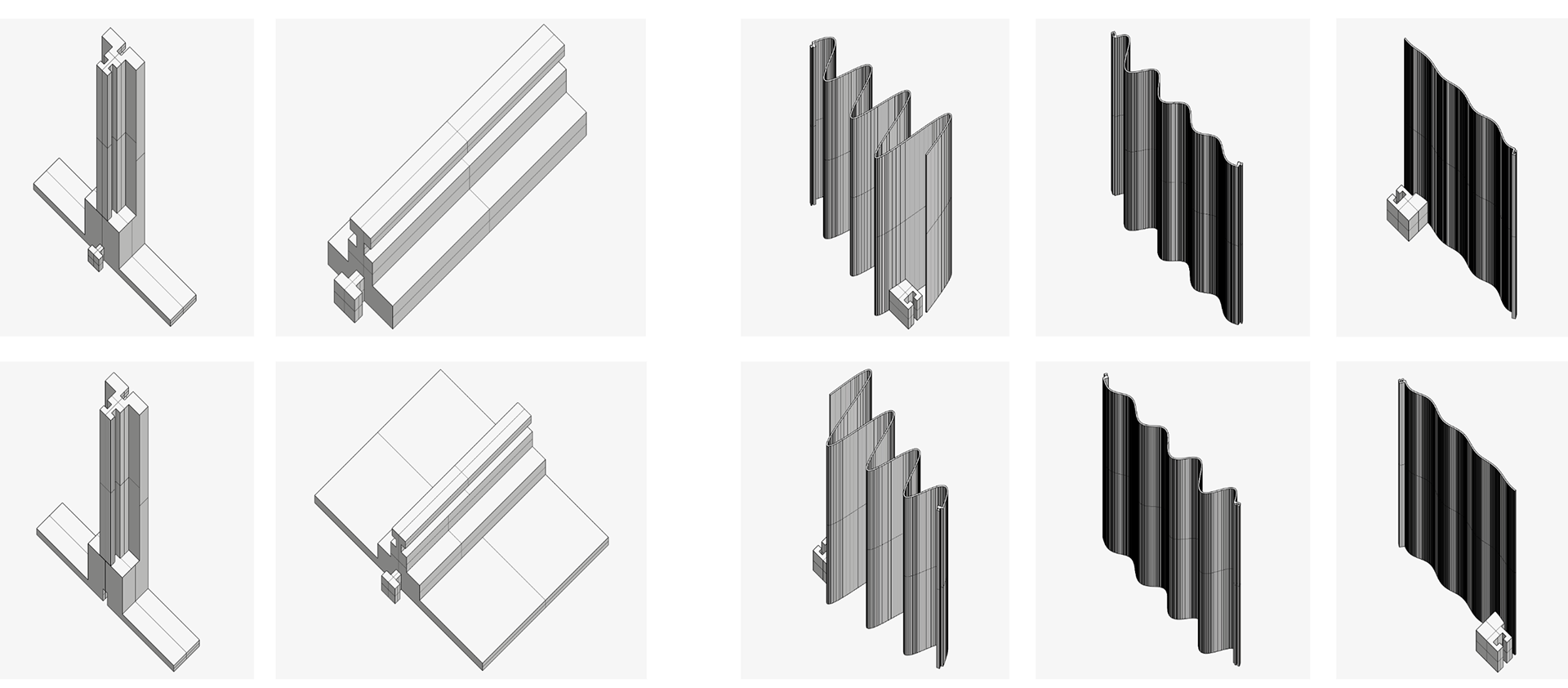

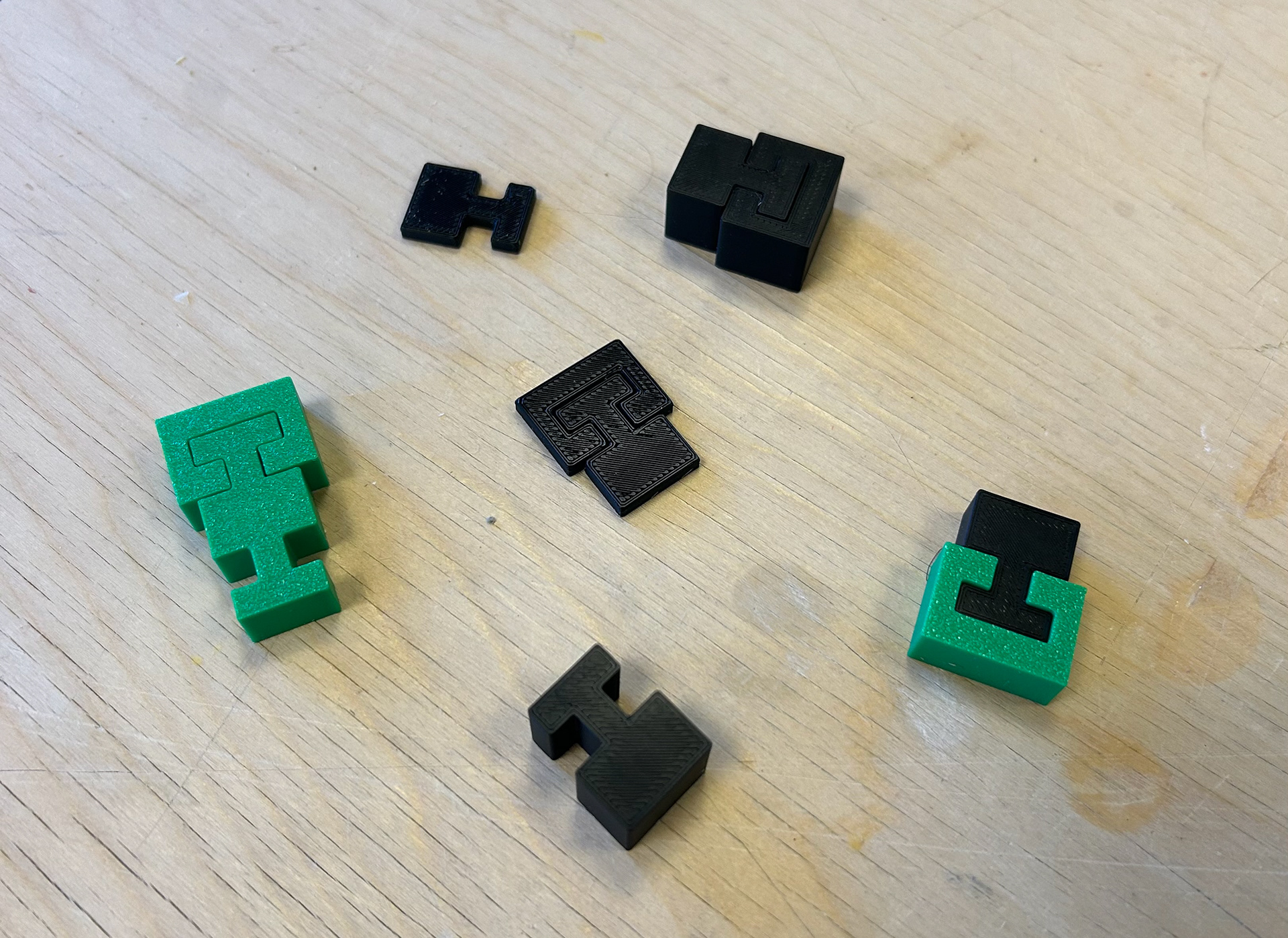

Connection & Panel Design Iterations

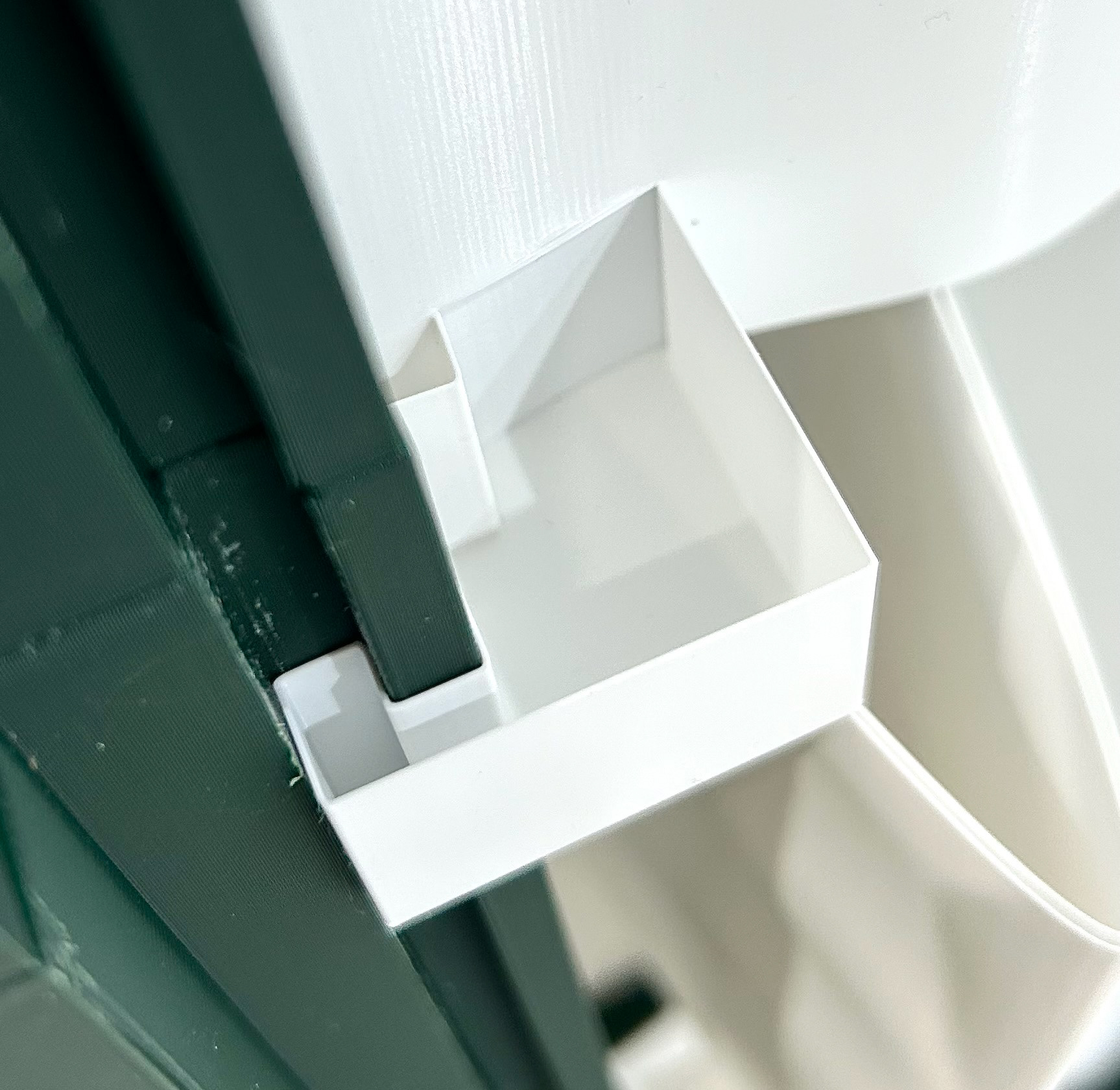

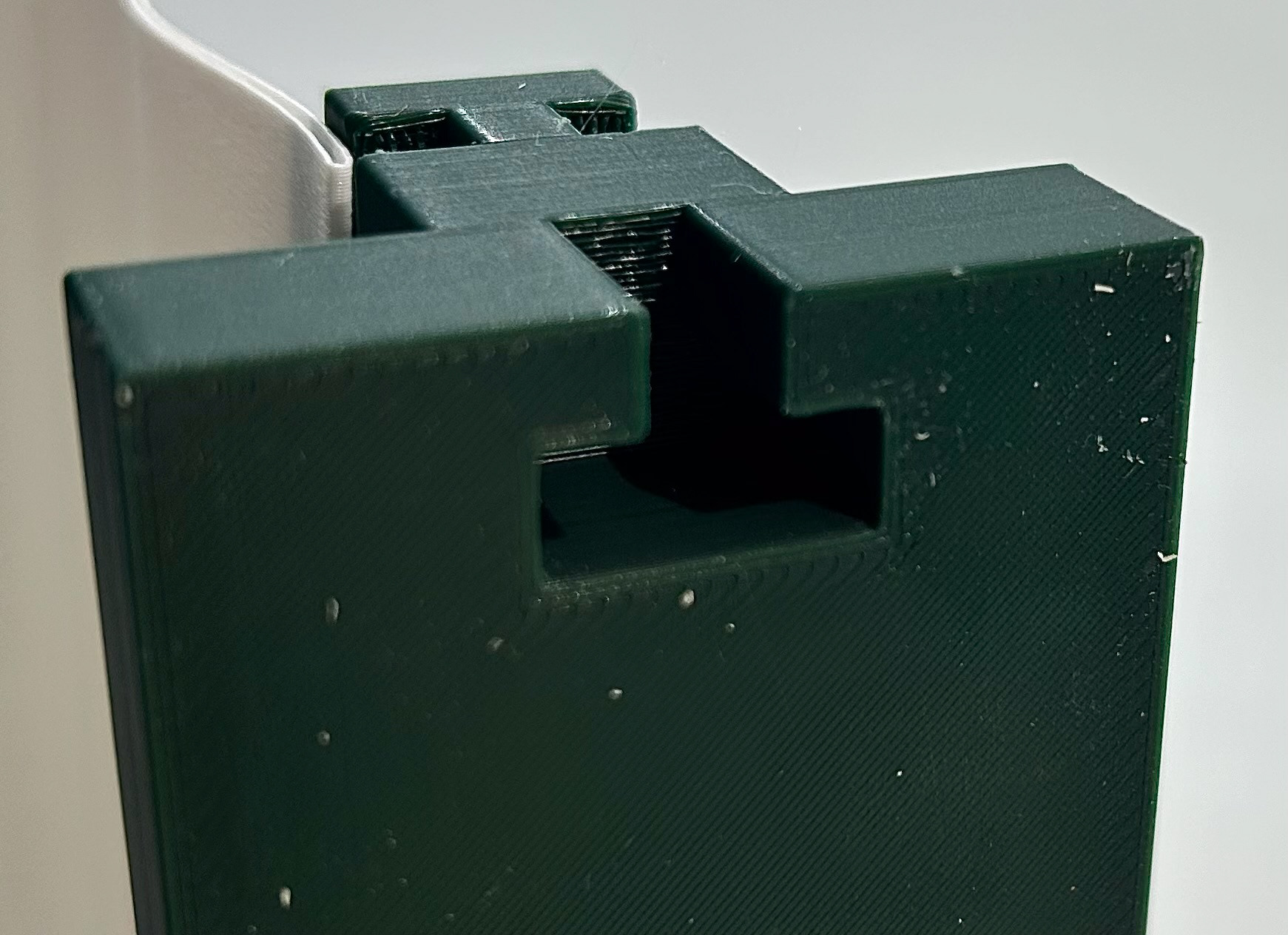

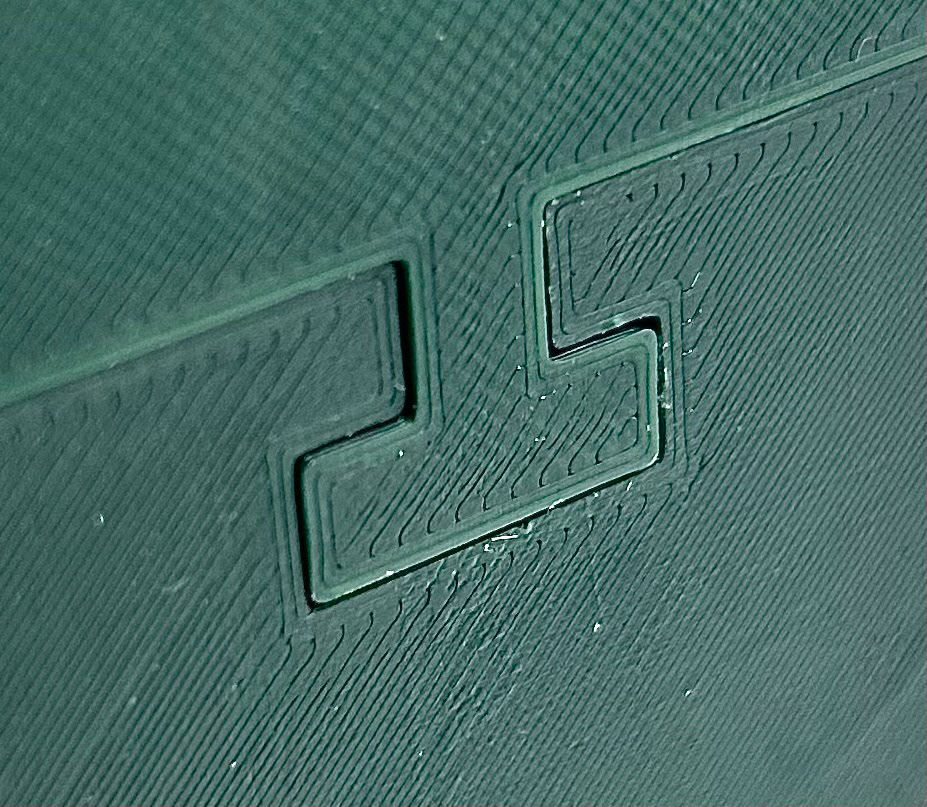

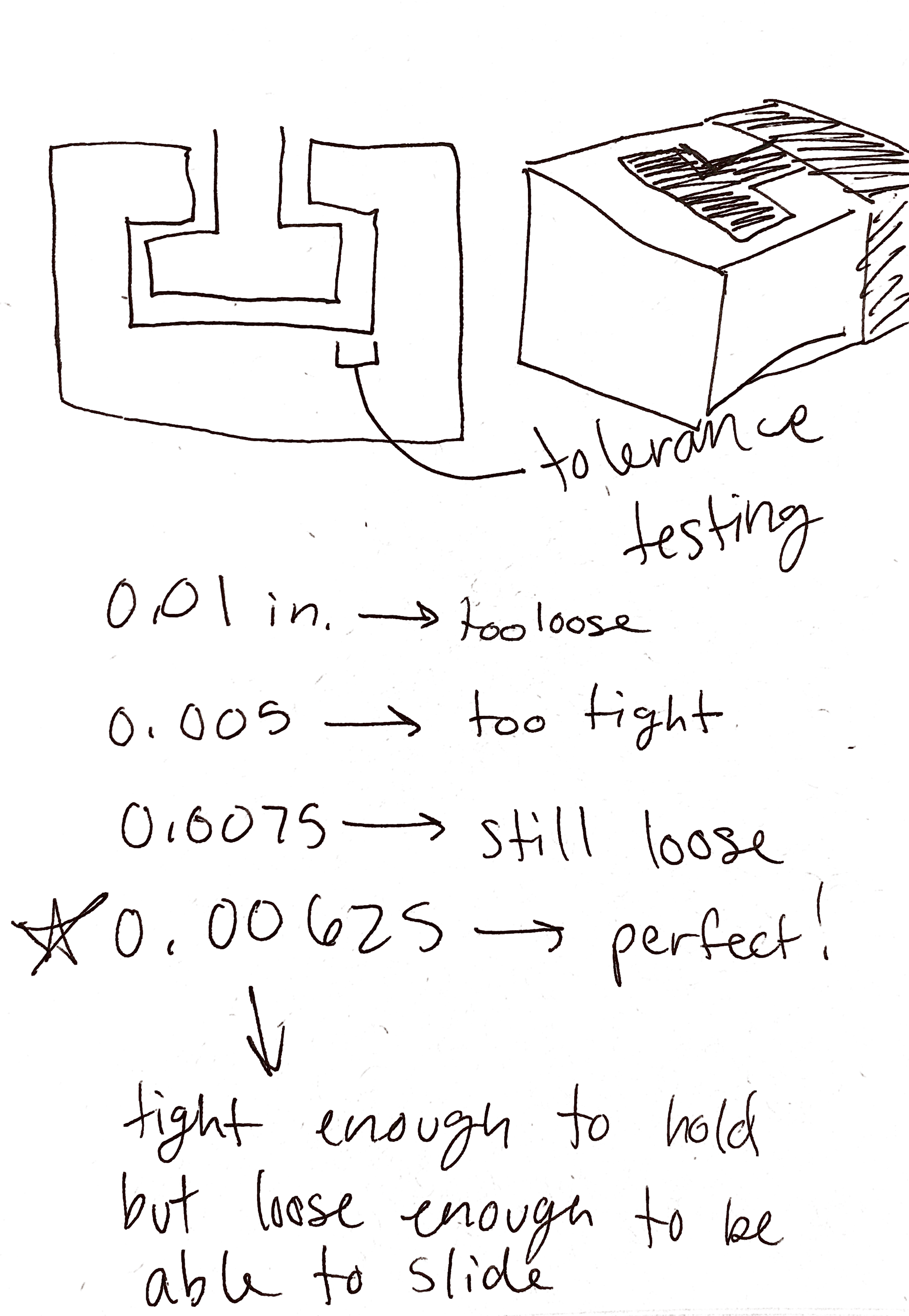

Initially, I began to design the connection itself before the paneling system. I knew I wanted to create a system that could be easily slid in and out of a "locked" position. With this in mind, I modified a common dado groove joint into a "T" shape that could have a male component slid into a series of female tracks. Once I had my connection decided, I also iterated a number of different panels. I wanted to focus on a design that would hone in on the filtration of light through it's facade and how the concentration of materiality can affect how the light passes through and the resulting effects.

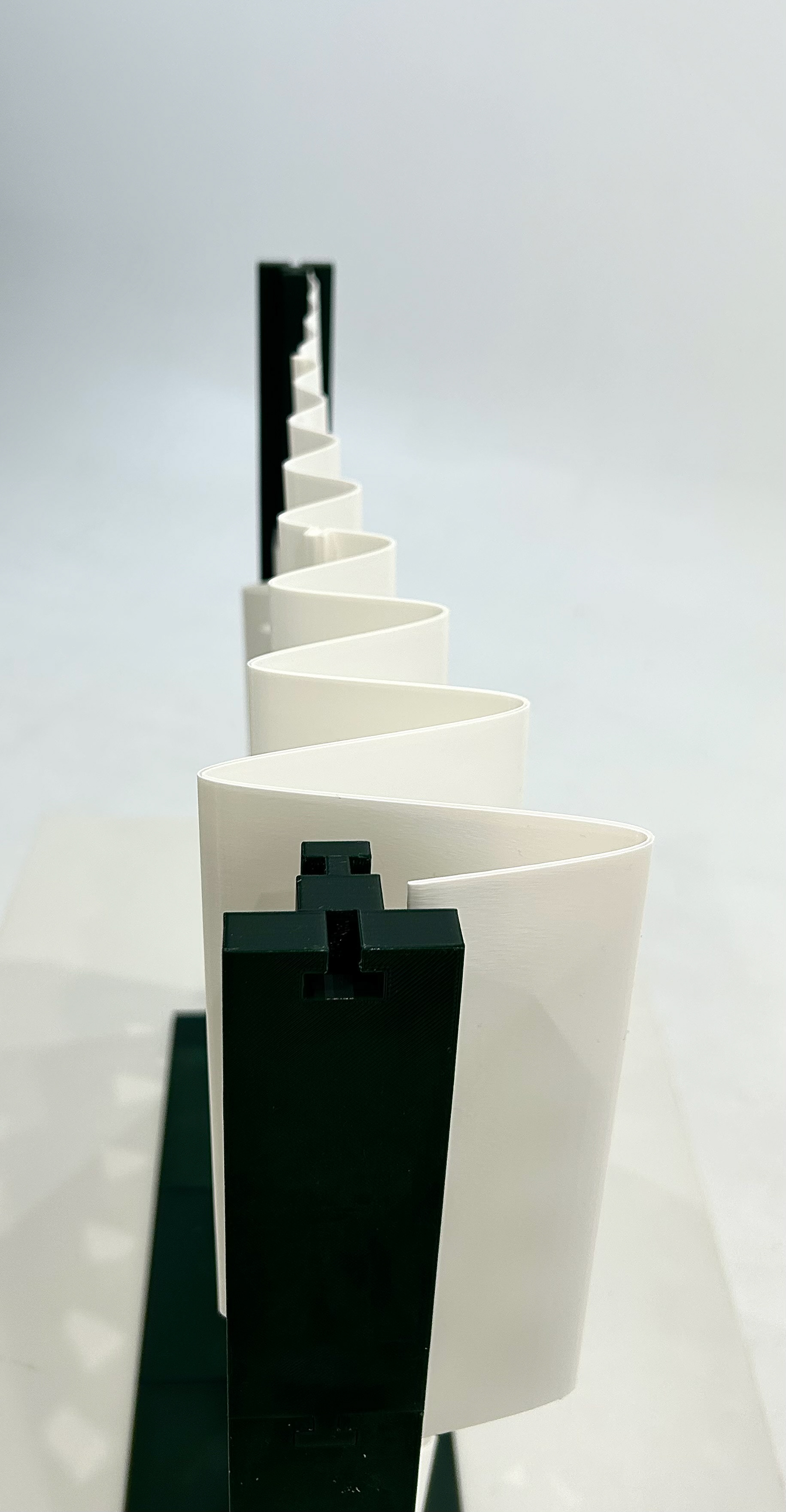

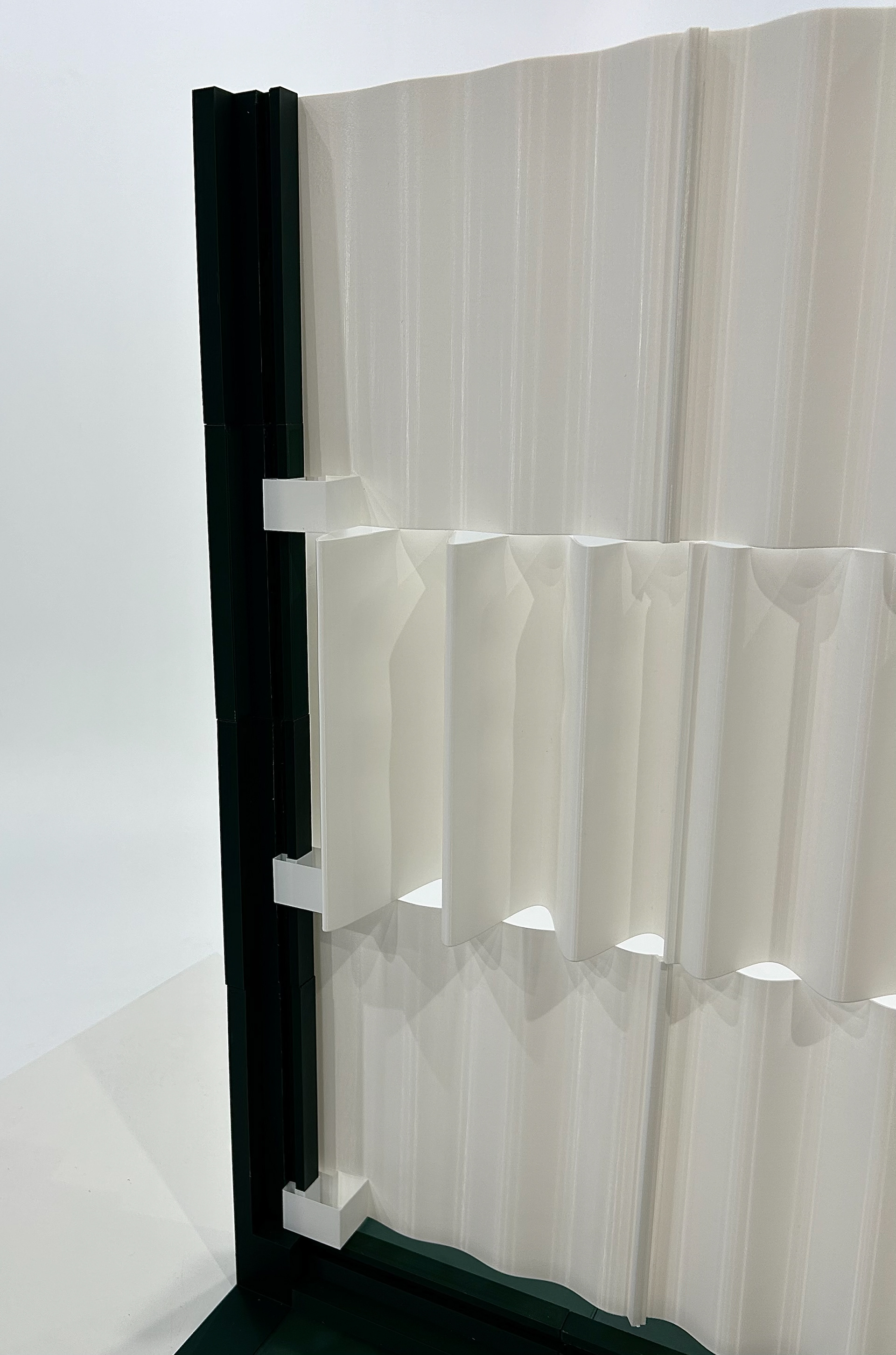

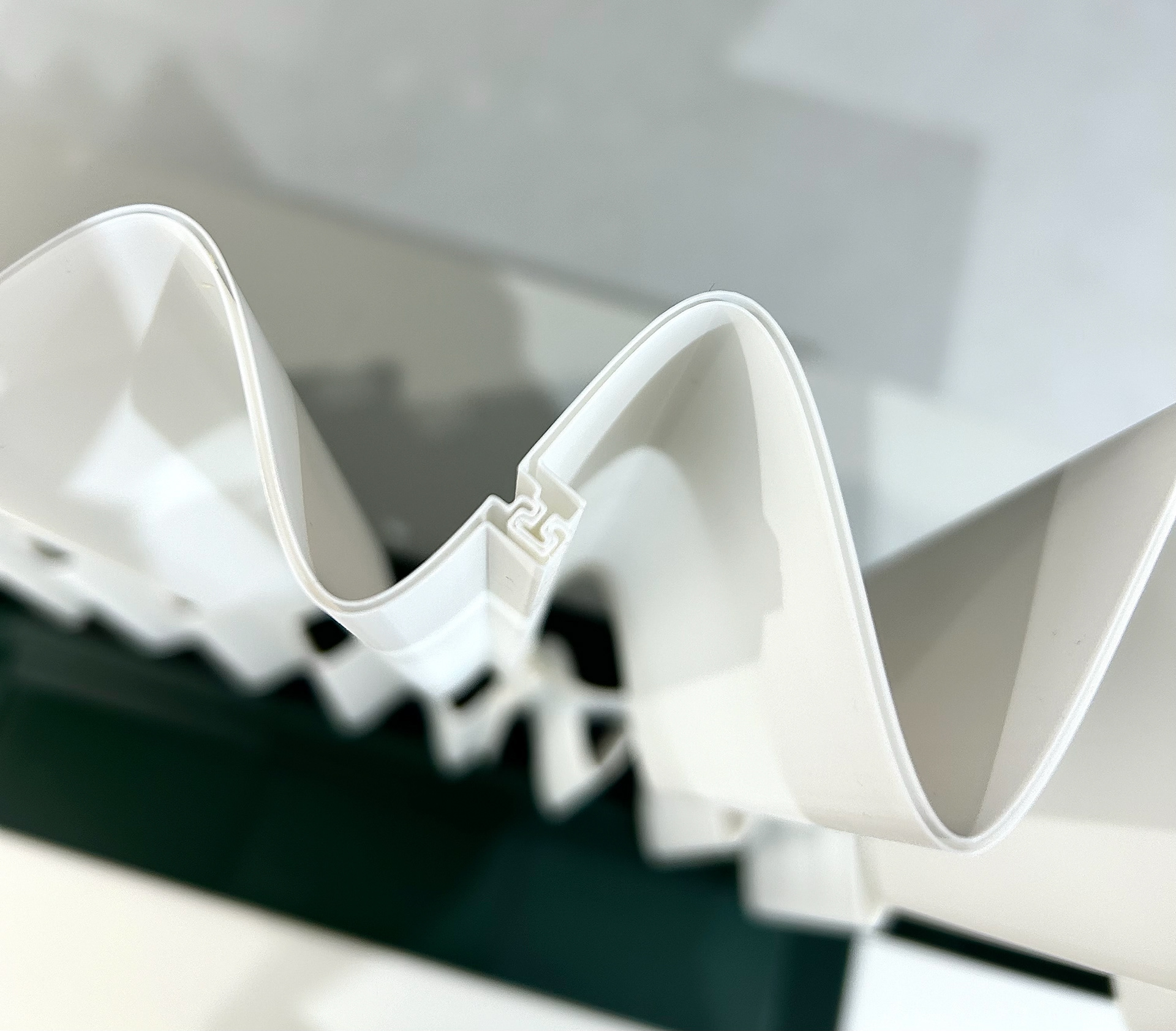

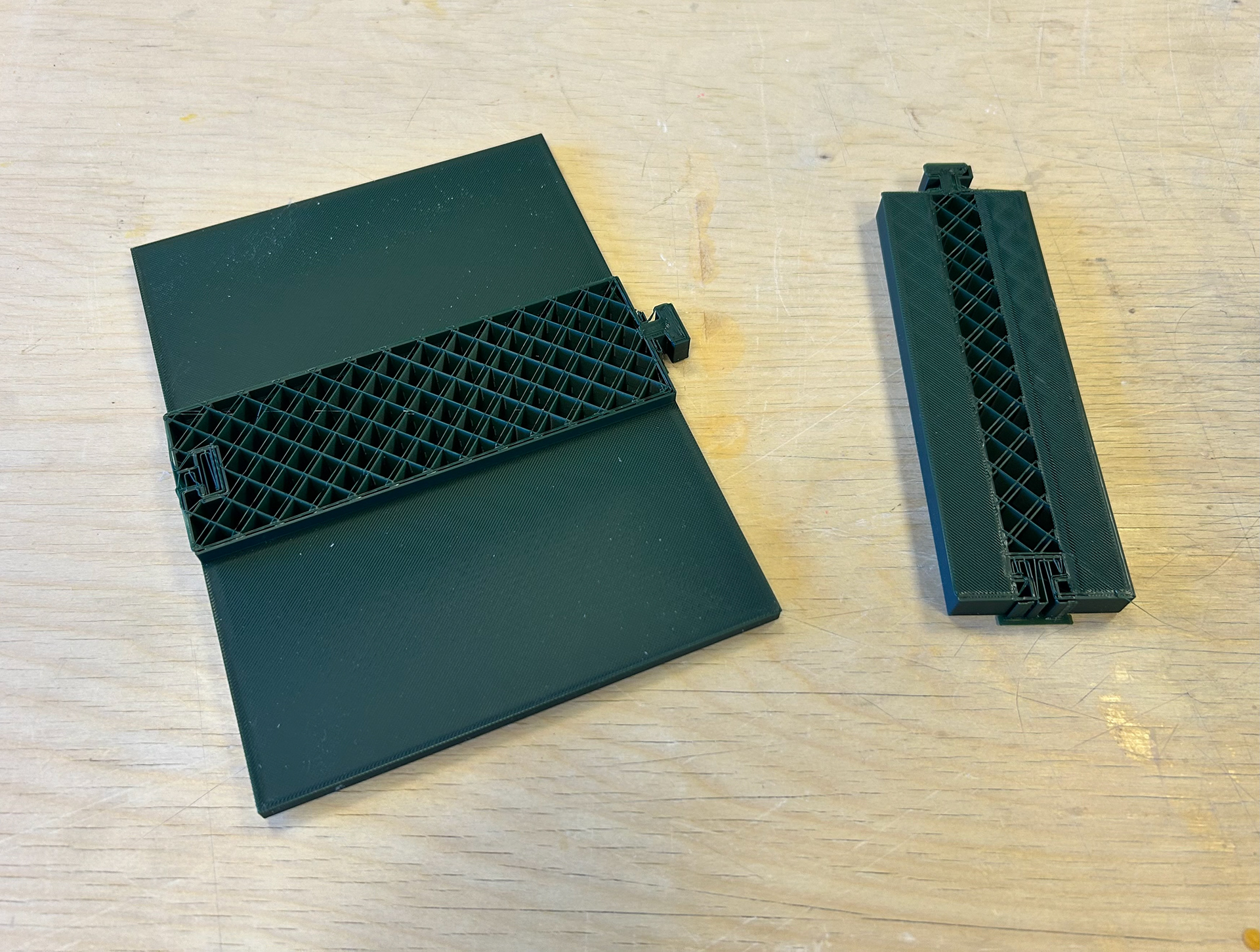

The final panel design I settled on for my screen consists of three modular 8 in. screen pieces that form the shape of an elongated sine wave when connected. In my mock up, three of these alternating layers are shown, and the full size version would be 12 layers high at a height of 8 ft.

Screen & Frame Modular Parts

System Connections

Fully Assembled Screen System

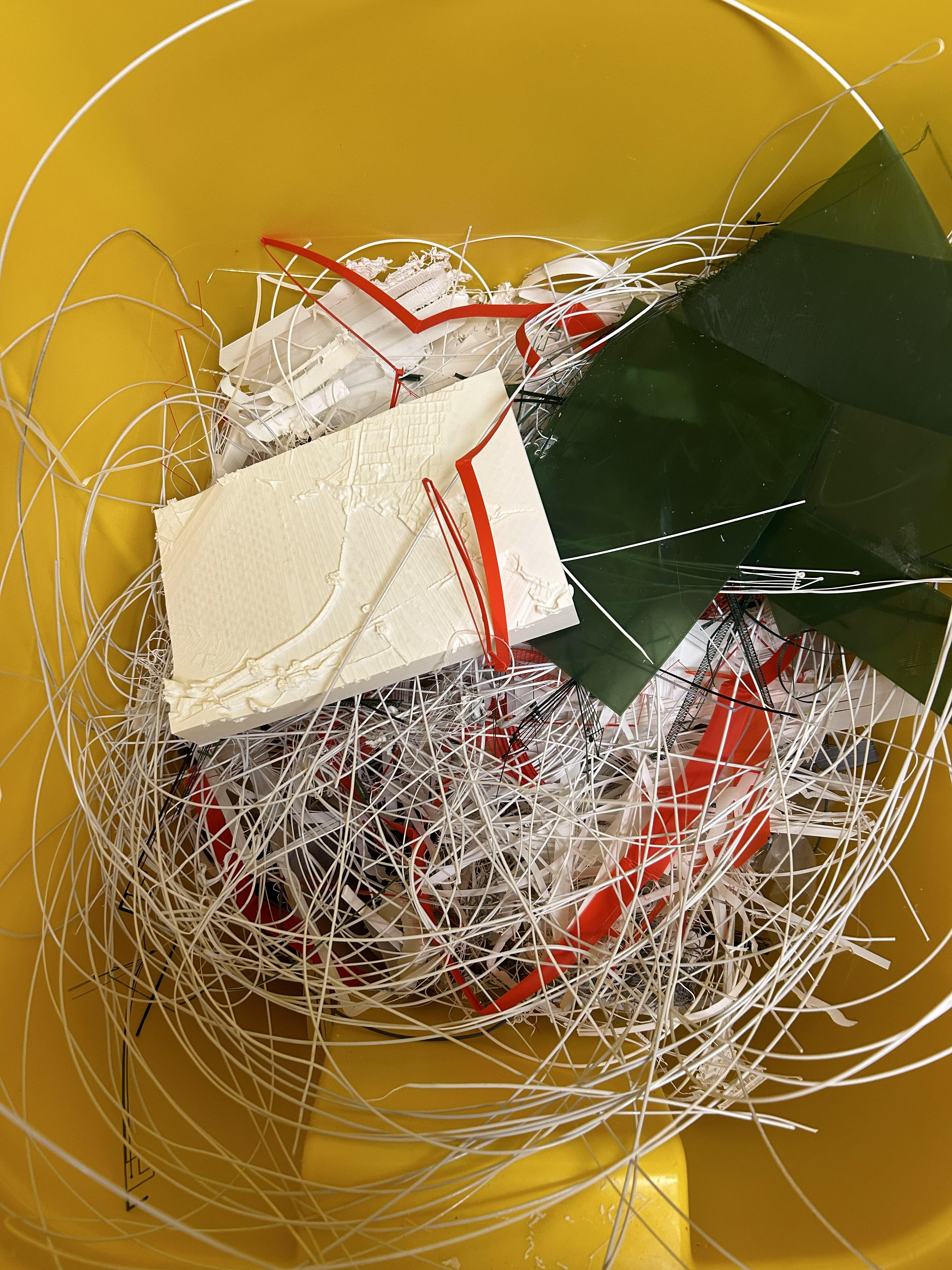

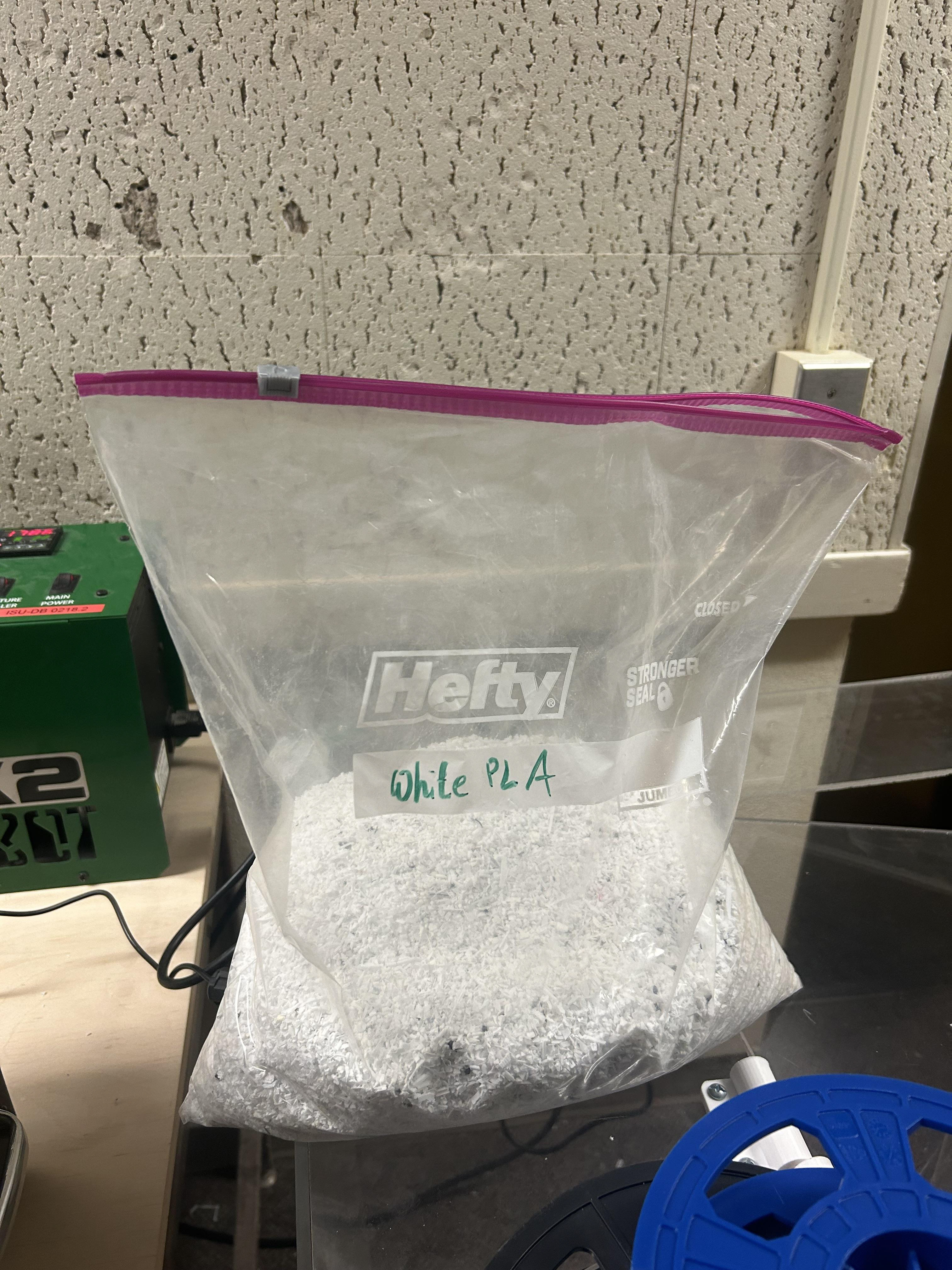

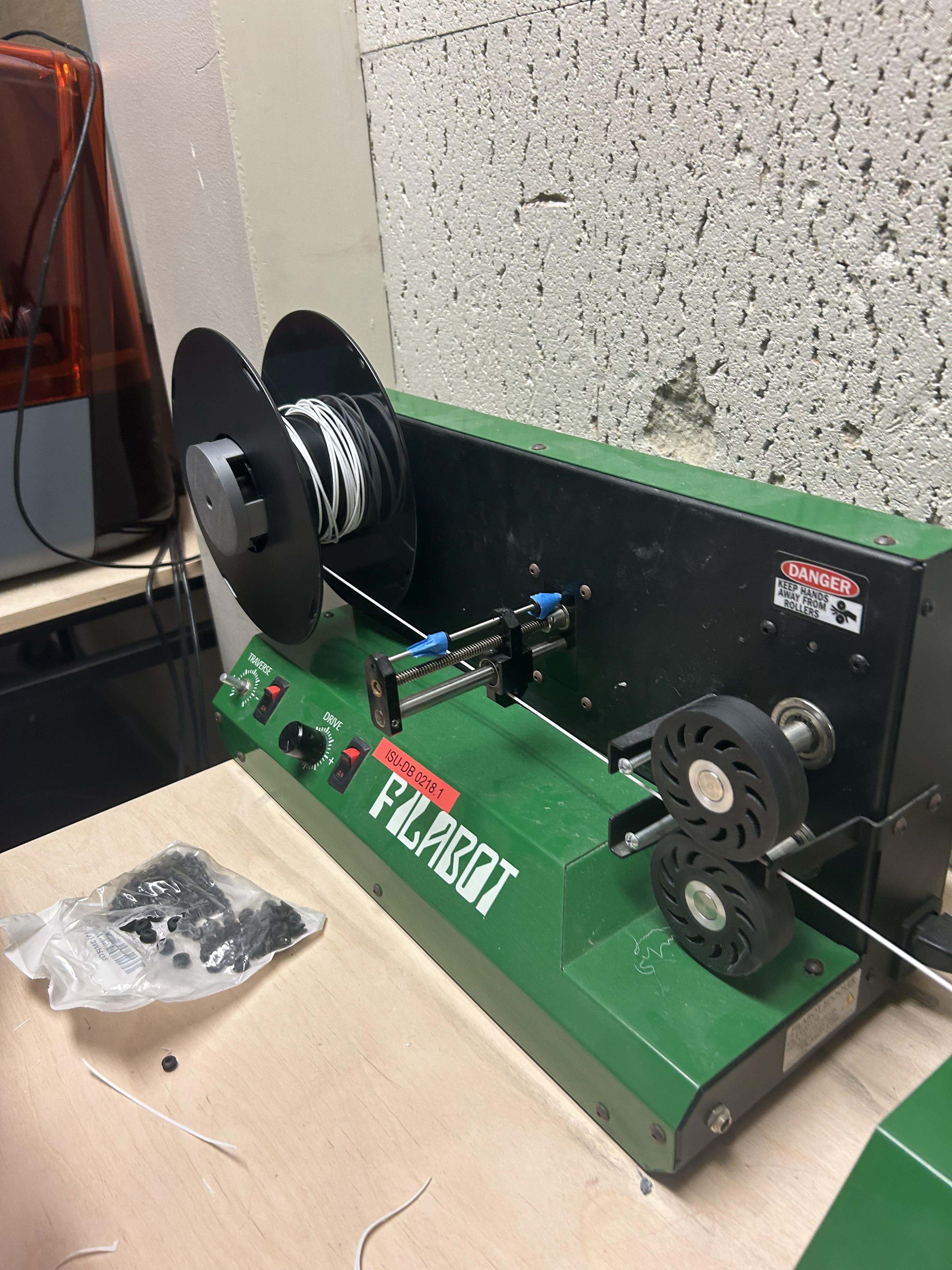

Recycled PLA 3D Printing Process

During the process of researching ways to recycle plastic materials, I came across the process of 3D print recycling. This process involves chopping, pelletizing, or stripping waste plastic from water bottles or waste prints and then extruding it through a heated nozzle to be rolled back into PLA filament. There are ways to make your own filament extruder, but I discovered that the Architecture Lab on campus has extrusion machines that have not been used in years. I was able to do enough research to get the machine back up and running and this is how I made the all of the filament to print my screen panels.

Test Prints & Tolerance Tests

Final Module Pieces

Final Assembly & Connections